Case Studies

Enertics Motor Health Monitor Application in Metal Foundry

Industry: Metal Manufacturing

Critical Application: Mixer Motor

Anomaly Diagnosed / Predicted: Belt Misalignment

For a detailed report of the case study, download the pdf below.

Downtime Reduction

31%

Unexpected Cost Savings

Rs. 200,000

Enertics asset health monitoring, diagnostics and predictive analytics system helped the Foundry customer in India by automatically diagnosing an early stage machine health issue, saving significant costs from unexpected machine failure & raw material wastage, as well as other costs from preventing plant downtime.

Enertics Motor Health Monitor Zinc Plating Plant

Industry: Plating Industry

Critical Application: Scrubber Motor

Anomaly Diagnosed / Predicted: Bearing Fault

For a detailed report of the case study, download the pdf below.

Downtime Reduction

28%

Unexpected Cost Savings

$35,000

Enertics asset health monitoring, diagnostics and predictive analytics automatically predicted a bearing fault on a critical machine used at the Zinc Plating plant, helping the customer preventing an unexpected failure causing significant unplanned repairs costs and material wastage.

Implementation of Smart Sensing at Food Processing Plant.

Industry: Food and Beverages

Critical Application: Scrapper Motor

Anomaly Diagnosed / Predicted: Enertics Automatically Generated Vibration and Magnetic Field Spectrums.

For a detailed report of the case study, download the pdf below.

Downtime Reduction

31%

Unexpected Cost Savings

Rs. 200,000

Enertics asset health monitoring, diagnostics and predictive analytics system automatically detected and

alerted the user on an early-stage electrical fault condition

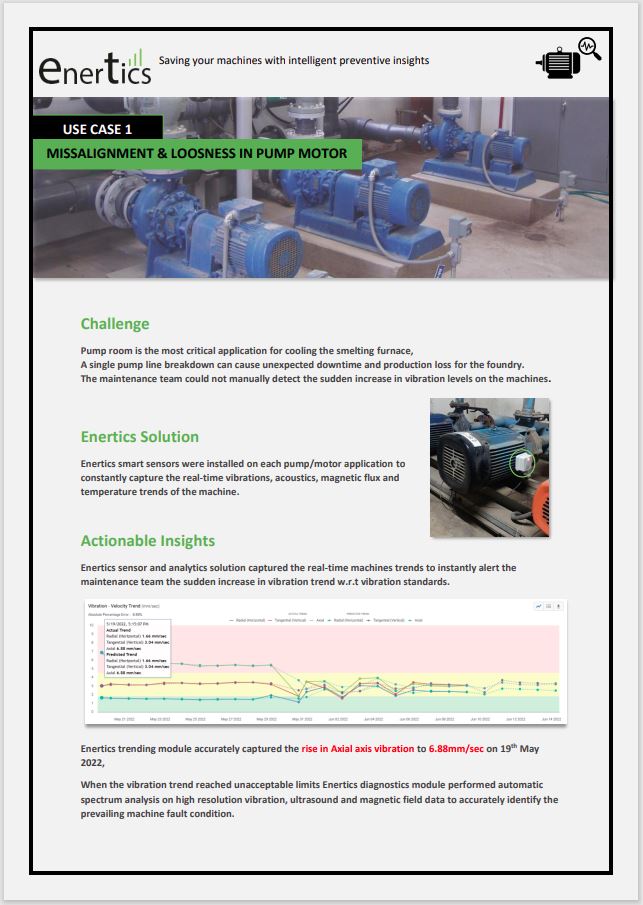

MISSALIGNMENT & LOOSENESS IN PUMP MOTOR

Industry: Metal Industry

Critical Application: Pump room

Anomaly Diagnosed / Predicted: Angular

Misalignment/Bent Shaft and Looseness on coupling side of the motor.

For a detailed report of the case study, download the pdf below.

Downtime Reduction

28%

Unexpected Cost Savings

$35,000

Enertics asset health monitoring, diagnostics and predictive analytics automatically detect an Angular Misalignment/Bent Shaft and Looseness on coupling side of the motor where the sensor was mounted.

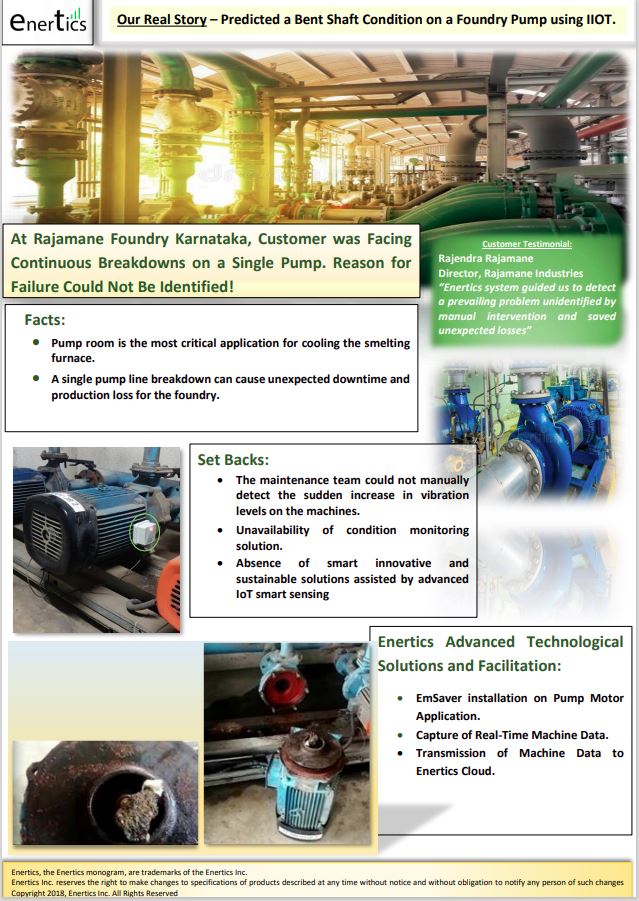

Predicted a Bent Shaft Condition on a Foundry Pump using IIOT

Industry: Food and Beverages

Critical Application: Pump Room

Anomaly Diagnosed / Predicted: Enertics Automatically Generated Vibration Spectrum

For a detailed report of the case study, download the pdf below.

Downtime Reduction

31%

Unexpected Cost Savings

Rs. 200,000

Enertics asset health monitoring, diagnostics and predictive analytics system automatically detected and

alerted the user on an early-stage electrical fault condition